Tesla

Tesla introduces new Supercharger post foundation for easy and fast installation

Tesla has introduced a new Supercharger post foundation to improve the charging station structure alongside speed and the efficiency of the installation.

Max de Zeghar, Chief of Supercharging at Tesla, has explained the key benefits of this new post foundation.

The new post foundation was installed at a Supercharger site in Hooksett, New Hampshire. This new design will replace the traditional concert-based installations.

The foundation will be composed of polypropylene, a durable lightweight and recyclable plastic. It has modular structure and can be stacked.

Unlike traditional Supercharger, which requires concrete pouring, building forms, and waiting for it to cure, which takes days and additional manpower. On the other hand, the new system can be installed by only a single person in a limited time.

These polypropylene units are pre-fabricated and shipped to the installation site. The key benefits of new foundation will is rapid and cost-efficient installation.

Source – X

On the other hand, concrete production is energy-intensive and increases carbon emissions. The new material is recyclable and minimizes local gravel for an environment friendly approach.

The charging chief emphasizes that charging infrastructure needs to scale 30 times to meet the future EV demand. Small efficiency improvements such as this one would contribute in Tesla’s goal of expanding the Supercharger network.

The new post highlights the modular, lightweight design makes it easier to deploy chargers in diverse location. That includes rural or remote areas where concrete installation might be impractical.

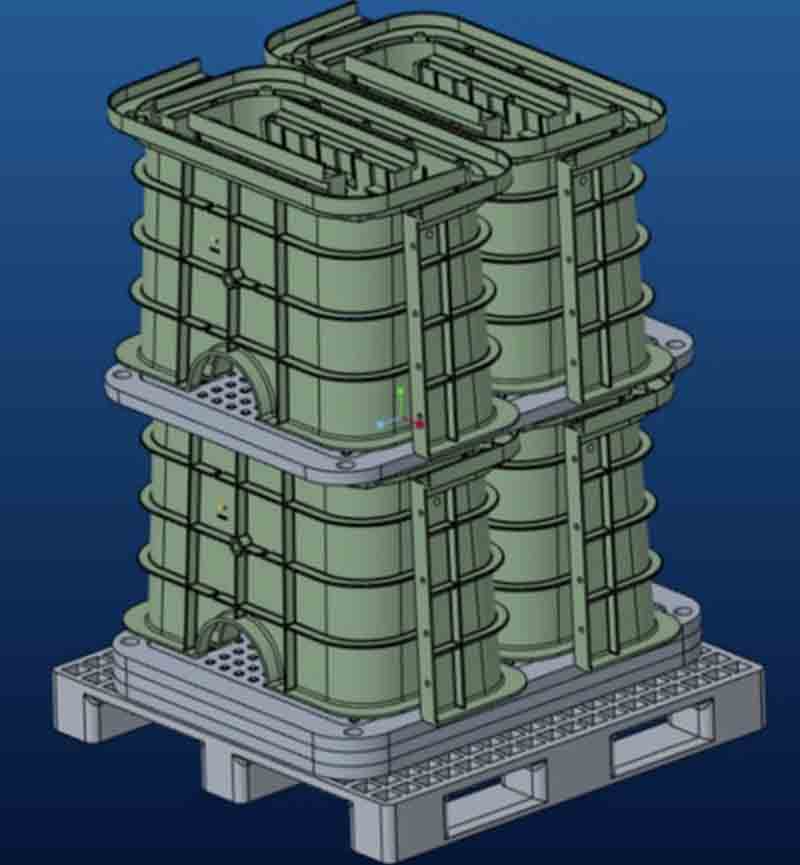

The image shared by the Tesla official shows the following structure details

The design includes stacked, cylindrical or box-like polypropylene structures with vents like opening. These may be designed for stability and gravel filling. These units are placed on a pallet, which hints that these are pre-assembled for a transport ready environment. The units are filled with local gravel on-site to provide weight and improve stability.